Introduction

This production line enjoys the advantages of high efficiency, low energy cost, high production capacity and economy and rationality.

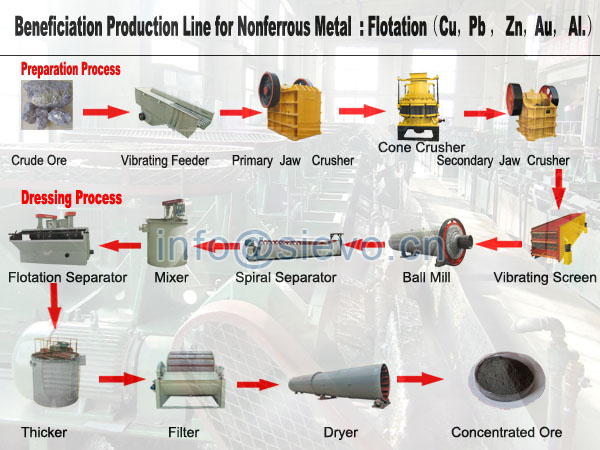

The procedure of the production line goes like this: the ore is first sent to jaw crusher for primary crushing. Then the ore with a proper size for secondary crushing will be sent into the ball mill for fine crushing and grinding. The ore powder discharged from the ball mill will be sent to the next procedure: classifying. Because of the different sedimentation rate due to the varied specific gravity, spiral classifier can clean and group the ore mixture. The cleaned and gouped mixture is sent to magnetic separator, due to the different susceptibility, magnetic substance can be separated from the mixture under magnetic.

The procedure of the production line goes like this: the ore is first sent to jaw crusher for primary crushing. Then the ore with a proper size for secondary crushing will be sent into the ball mill for fine crushing and grinding. The ore powder discharged from the ball mill will be sent to the next procedure: classifying. Because of the different sedimentation rate due to the varied specific gravity, spiral classifier can clean and group the ore mixture. The cleaned and gouped mixture is sent to magnetic separator, due to the different susceptibility, magnetic substance can be separated from the mixture under magnetic.

Crusher Equipment

- Sand Making Machine

- Stone Making Machine

- Stone crusher

- Jaw Crusher

- Impact Crusher

- Cone Crusher

- Single-stage Hammer Crusher

- Ring Hammer Crusher

- Hammer Crusher

- Vertical Shaft Impact Crusher

- Roller Crusher

- Fine Impact Crusher

- Rod Mill

- Mobile Crusher Station

- Vibrating Feeder

- Vibrating Screen

- Belt Conveyor

- Sand Washer

- Stone Washer

Beneficiation Equipment

Construction Material

- Cement Production Line

- Cement Rotary Kiln

- Cyclone Preheater

- Cement Mill

- Raw Mill

- Coal Mill

- Vertical Mill

- Powder Concentrator

- Pulse Bag Dust Collector

- Rotary Kiln

- Lime Rotary Kiln

- Vertical Preheater

- Vertical Cooler

- Active lime assembly line

- Autoclaved Aerated Concrete Equipment

- Steel Wire Belt Elevator

- Chain Bucket Elevator

- Screw Weigher

- Belt Scale

PRODUCT

Flotation Machine

This type of flotation machine is formed by U through solid, hollow shaft inflation, suspension rotor and new type impeller. The cone impeller lean backwards, the blending quantity is big and the pressure head is small, the advantages are: simple structure and low energy consumption. Inside the impeller, there is air distributor, which distributes air into most parts of impeller evenly.

When flotation machine works, slurry is inhaled from the bottom of the trough to the space between impellers. Meanwhile, the low pressure air send by fan is sent to this area through the air distributor in the hollow shaft. After sufficient mixing, the slurry is pushed out by the impeller, and then goes to the whole trough. When the froth rises to the stable level, after the enrichment processing, froth overflows to the froth trough from the overflow weir. Another part of ore slurry flows to lower part of impeller for the re-mix with air. The remained slurry flows to the next trough until becomes residue.

Main Technical Parameters:

SF Series:

| Model | Volume(m³) | Size of tank (L×W×H) (mm) | Impeller Dia. (mm) | Impeller speed(r/min) | Capacity(m³/min) | Motor power(kw) | Air flow sucked (m³/㎡min) | Weight of singe tank(kg) |

| SF-0.15 | 0.15 | 500×500×600 | 200 | 536 | 0.06-0.18 | 1.5/0.55 | 0.8-1 | 269 |

| SF-0.37 | 0.37 | 700×700×750 | 296 | 386 | 0.2-0.4 | 1.5/0.55 | 0.8-1 | 468 |

| SF-0.7 | 0.7 | 820×900×950 | 350 | 400 | 0.3-0.9 | 3/1.1 | 0.8-1 | 805 |

| SF-1.2 | 1.2 | 1100×1100×1100 | 450 | 312 | 0.6-1.2 | 5.5/1.1 | 1-1.2 | 1373 |

| SF-2.8 | 2.8 | 1700×1600×1150 | 550 | 268 | 1.5-3.5 | 11/1.5 | 1-1.2 | 2138 |

| SF-4 | 4 | 1850×2050×1200 | 650 | 220 | 2--4 | 15/1.5 | 1-1.2 | 2582 |

| SF-8 | 8 | 2200×2900×1400 | 760 | 191 | 4--8 | 30/1.5 | 0.9-1 | 4129 |

| SF-10 | 10 | 2200×2900×1700 | 760 | 191 | 5--10 | 30/1.5 | 0.9-1 | 4486 |

| SF-16 | 16 | 2850×3800×1700 | 760 | 191 | 5--16 | 30×2/1.5 | 0.9-1 | 8320 |

| SF-20 | 20 | 2850×3800×2000 | 760 | 191 | 5--20 | 30×2/1.5 | 0.9-1 | 9828 |

KYF Series:

| Model | Size of tank (mm) | Single effective volume(kg) | Effective volume(m³) | Capacity(m³/min) | Motor of main shaft | Impeller | Motor of scraper | Wind pressure of blower (kpa) |

| Power(kw) | Dia.(mm) | Power(kw) | ||||||

| KYF-1 | 1000×1000×1100 | 826.31 | 1 | 0.2-1 | 4 | 340 | 1.1 | ≥12.6 |

| KYF-2 | 1300×1300×1250 | 1419 | 2 | 0.4-2 | 5.5 | 410 | 1.1 | ≥14.7 |

| KYF-3 | 1600×1600×1400 | 1885 | 3 | 0.6-3 | 7.5 | 480 | 1.5 | ≥19.8 |

| KYF-4 | 1800×1800×1500 | 2206 | 4 | 1.2-4 | 11 | 550 | 1.5 | ≥19.8 |

| KYF-8 | 2200×2200×1950 | 3600 | 8 | 3-8 | 15 | 630 | 1.5 | ≥21.6 |

| KYF-16 | 2800×2800×2400 | 5900 | 16 | 4-16 | 30 | 740 | 1.5 | ≥25.5 |

| KYF-24 | 3100×3100×2900 | 7500 | 24 | 4-24 | 30 | 800 | 1.5 | ≥30.4 |

| KYF-38 | 3600×360×3400 | 10300 | 38 | 10-38 | 37 | 880 | 1.5 | ≥34.3 |

Please input your inquiry in below form, we will get back to you as soon as possible!

Shanghai Sievo Ball Mill Manufacturer All rights reserved @ be by 2012 E-mail: info@sievo.cn

Address: No.299 Shenzhou Road,Fengxian District,Shanghai,China

Address: No.299 Shenzhou Road,Fengxian District,Shanghai,China