Introduction

This production line enjoys the advantages of high efficiency, low energy cost, high production capacity and economy and rationality.

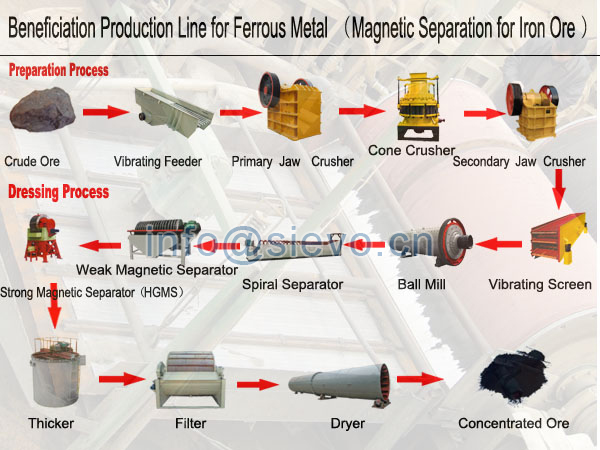

The procedure of the production line goes like this: the ore is first sent to jaw crusher for primary crushing. Then the ore with a proper size for secondary crushing will be sent into the ball mill for fine crushing and grinding. The ore powder discharged from the ball mill will be sent to the next procedure: classifying. Because of the different sedimentation rate due to the varied specific gravity, spiral classifier can clean and group the ore mixture. The cleaned and gouped mixture is sent to magnetic separator, due to the different susceptibility, magnetic substance can be separated from the mixture under magnetic.

The procedure of the production line goes like this: the ore is first sent to jaw crusher for primary crushing. Then the ore with a proper size for secondary crushing will be sent into the ball mill for fine crushing and grinding. The ore powder discharged from the ball mill will be sent to the next procedure: classifying. Because of the different sedimentation rate due to the varied specific gravity, spiral classifier can clean and group the ore mixture. The cleaned and gouped mixture is sent to magnetic separator, due to the different susceptibility, magnetic substance can be separated from the mixture under magnetic.

Crusher Equipment

- Sand Making Machine

- Stone Making Machine

- Stone crusher

- Jaw Crusher

- Impact Crusher

- Cone Crusher

- Single-stage Hammer Crusher

- Ring Hammer Crusher

- Hammer Crusher

- Vertical Shaft Impact Crusher

- Roller Crusher

- Fine Impact Crusher

- Rod Mill

- Mobile Crusher Station

- Vibrating Feeder

- Vibrating Screen

- Belt Conveyor

- Sand Washer

- Stone Washer

Beneficiation Equipment

Construction Material

- Cement Production Line

- Cement Rotary Kiln

- Cyclone Preheater

- Cement Mill

- Raw Mill

- Coal Mill

- Vertical Mill

- Powder Concentrator

- Pulse Bag Dust Collector

- Rotary Kiln

- Lime Rotary Kiln

- Vertical Preheater

- Vertical Cooler

- Active lime assembly line

- Autoclaved Aerated Concrete Equipment

- Steel Wire Belt Elevator

- Chain Bucket Elevator

- Screw Weigher

- Belt Scale

PRODUCT

Magnetic Separator

The magnetic separator is characterized by a turbulent magnetic field and high separation factor, advanced structure, light weight, reliable operation and convenient maintenance. The magnetic separator is very suitable for the districts that are short of water so that water resource may be saved and ore dressing coasts may be reduced. It develops a new way for mining and utilization of magnetite. The separator may be driven by diesel engine. It may be used in the districts lacking of electricity. The magnetic separators with different magnetic induction intensities that are used for different minerals may be developed according to user’s specific need besides the existing pattern products. The existing series products may meet the needs of concentrators of large, medium and small-sized mines. We welcome users to come to our company for business contact. Our company has industrial prototypes and may do pilot tests for users.

Application: automatic separation/recovery of ferrous and non-ferrous materials.

Main features of Magnetic Separator:

Custom-designed and manufactured separation solutions for specific applications, combining conveying, vibratory, screening, magnetic separation and metal detection equipment;

Single operating console for complete control over the whole system;

For conducting laboratory tests with your material please contact our sales department.

Please attach a completed questionnaire to quotation requests.

Main Technical Parameters of Magnetic Separator:

| Model | Cylinder dia.(mm) | Cylinder length(mm) | Rotary speed of cylinder(r/min) | Capacity (t/h) | Feeding size(mm) | Power (kw) | Weight (kg) |

| 612 | 600 | 1200 | ﹤35 | 10~20 | 2~0 | 1.5 | 1445 |

| 618 | 600 | 1800 | ﹤35 | 15~30 | 2~0 | 2.2 | 1655 |

| 718 | 750 | 1800 | ﹤35 | 20~45 | 2~0 | 22 | 1992 |

| 918 | 900 | 1800 | ﹤35 | 40~60 | 3~0 | 3 | 3162 |

| 924 | 900 | 2400 | ﹤28 | 45-70 | 3~0 | 4 | 3887 |

| 1024 | 1050 | 2400 | ﹤20 | 60-120 | 3~0 | 5.5 | 4319 |

| 1218 | 1200 | 1800 | ﹤18 | 80-140 | 3~0 | 5.5 | 5263 |

| 1230 | 1200 | 3000 | ﹤18 | 100-180 | 3~0 | 7.5 | 6325 |

| 1530 | 1500 | 3000 | ﹤16 | 150-260 | 3-0 | 11 | 9500 |

Please input your inquiry in below form, we will get back to you as soon as possible!

Shanghai Sievo Ball Mill Manufacturer All rights reserved @ be by 2012 E-mail: info@sievo.cn

Address: No.299 Shenzhou Road,Fengxian District,Shanghai,China

Address: No.299 Shenzhou Road,Fengxian District,Shanghai,China